Description

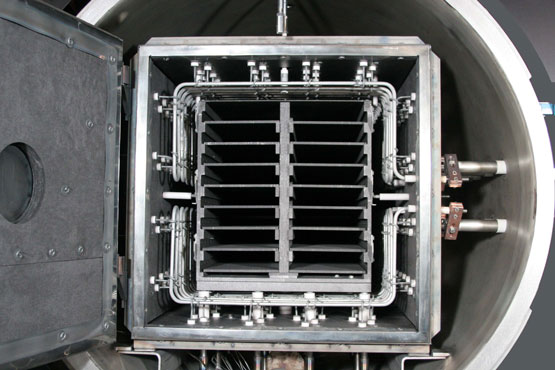

Elnik’s GraphMIM 2000G series furnaces process any iron based metal with any binder in a one step second stage debind and sinter cycle without having to move the parts. This is accomplished through the use of a Graphite retort with calibrated gas distribution across all of the individual parts.

The gas management system consists of a mass flow controller for the work zone and a partial pressure valve at the specially designed and modified dry vacuum pump. Different flow of gases into the work zone and a partial pressure inside the retort minimize binder materials sticking to the cold walls of the furnace chamber. The retort has gas distribution system via a calibrated hole pattern to ensure that the heated gas flows evenly across each shelf inside the retort.

Additionally, 6 zone temperature control front, middle, and rear, for the top and bottom around the retort.

The even gas flow across the shelves guarantees very close temperature control resulting in excellent temperature uniformity throughout the usable work zone of the furnace.

The construction of the Elnik Systems retort ensures, that the parts are fully debound through the even gas flow during the debind cycle and sintered to full density through the close temperature uniformity during the sinter cycle.