Our People Make All the Difference.

Elnik’s success is driven by the dedicated hands that help craft our equipment, the energetic service team helping customers, the detailed engineers designing our state of the art systems, the support and administrative staff running the day to day operations and our leaders developing the vision and missions for our future.

Innovation. Quality. Experience. Excellence.

Our People Make All the Difference.

ELNIK History Timeline

We got our start in 1969 and the rest is history…

Elnik Instruments was established as a wholly owned subsidiary of W.H. Joens & Co. in Germany marketing temperature controllers, recorders and programmers for industrial furnaces, vacuum furnaces plus a variety of plastic extrusion and injection molding machinery.

1969

1982

Elnik Instruments entered the vacuum furnace industry with focused efforts on vacuum furnace systems for Raytheon Company, Waltham MA.

Elnik Systems was formed to meet growing demand for custom vacuum furnaces primarily for the military industry.

1986

1995

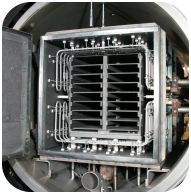

Elnik developed a ”one-step” debind and sinter partial pressure furnace to meet the needs of the growing MIM market. The MIM 3000 furnace provides a very cost-effective alternative to the two-furnace technology being used at the time.

Elnik Systems moves into a new state-of-the-art facility housing DSH Technologies, an Elnik affiliate, in Cedar Grove, NJ. Elnik began to standardize its MIM furnace line and continues to manufacture the most advanced MIM furnaces and debinding ovens in the world for one-step debinding and sintering processes.

1999

2004

Elnik continues pushing innovation of its furnace capabilities, introducing AccuTemp™ Temperature control allowing each temperature zone inside its furnace to be controlled within +/- 1º of its set point. Elnik Developed a Catalytic Debind Oven to be used to process BASF Catamold and Other POM based Feedstocks.

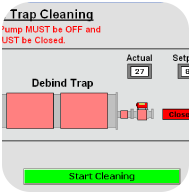

Elnik added automatic cleaning features of its Vacuum Pump and Binder Traps significantly reducing the manual maintenance time required of its systems.

2005

2006

Elnik introduces a full line of graphite MIM furnaces called the GraphMIM 2000 to its line for lower cost MIM processing of iron materials. This system contains all the same innovative functions as its MIM3000 series furnace.

Elnik Develops a Metal and Ceramic debinding oven made for POM based metal and ceramic Feedstocks. This system has enhanced controllability of temperature, Nitric Acid flow and gas flow.

2012

2015

Elnik developed a laboratory furnace for the MIM industry, MIM3001L. Having all the same processing characteristics as its larger production furnace syblings, this LAB furnace allows for an easy scale up from R+D to Production processing without having to reinvent the wheel. This furnace is also sized and functional for the Additive Manufacturing world involved with binder based 3D printing.

Elnik Systems establishes its first European based service and parts facility, Elnik Systems, GmbH. Located in Waldachtal, Germany, this facility will contain spare parts and a service technician.