Description

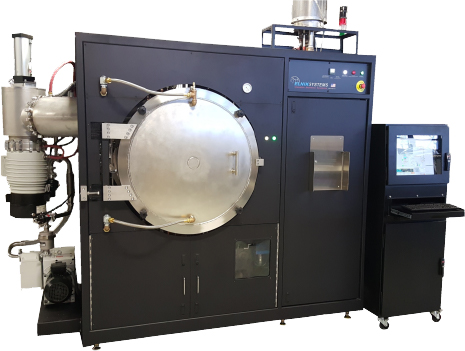

Elnik’s MIM 3001L Lab sized MIM furnace processes any metal with any binder in a one step second stage debinding and sintering cycle, without having to move the parts. This is accomplished through a gas tight refractory metal retort with a gas management system. This furnace has:

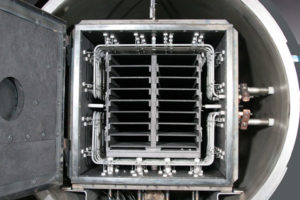

Laminar gas flow, which guarantees consistent parts every process run. The gas management system consists of mass flow controllers for the retort and hot zone, and a partial pressure valve at the inlet of a specially designed and modified dry vacuum pump. Different flows of gases into the hot zone and retort guarantee that only a minimum of binder materials stick to the cold walls of the furnace. The retort has gas plenums on each side with a hole pattern to ensure that heated gas flows evenly across each shelf in the retort.

ACCU-Temp, a linearization technique which allows each of the six zones within the furnace to run within +/- 1 degree C of the actual temperature inside the retort. Wire certified thermocouples with different calibration points are used and the difference in calibration is corrected via this proprietary linearization program. This enables the user to achieve higher densities of MIM materials by programming the sintering temperature closer to the actual melting temperature without running the risk of overheating and therefore distorting the parts.

Automatic operation, which allows for completely computerized controls for flow, temperature, and partial pressure. A leak check mode for the vacuum integrity is build in. All operation data including temperature, gas flows, pressure, and total power consumption is logged for each run.

A maintenance screen, which reminds the user to service the pumps, change the thermocouples, and more for easy cleaning of the sintering furnaces.